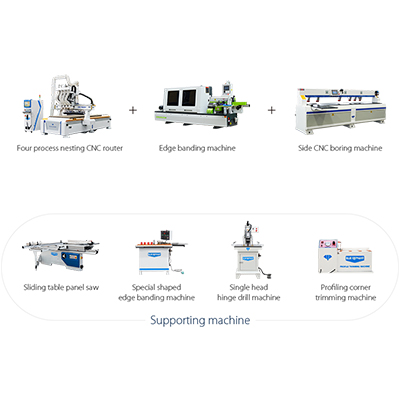

Entry-level Panel Furniture Production Line for Sale in Colombia, Australia, Singapore

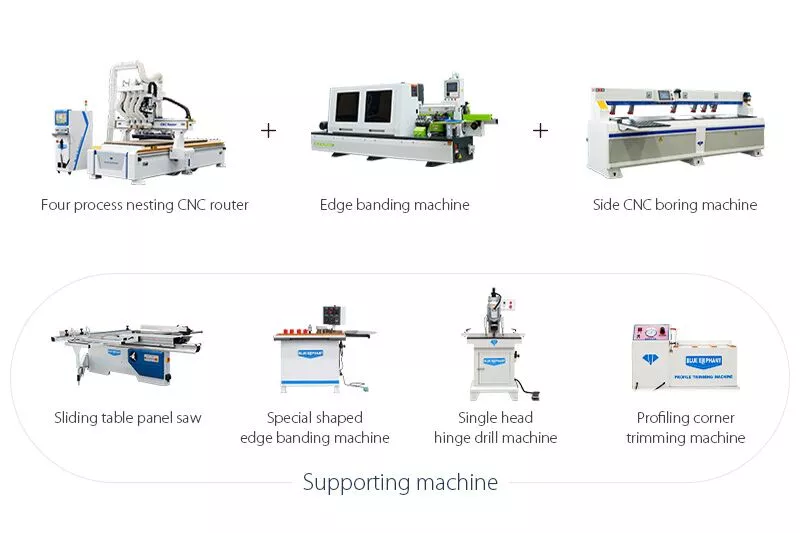

☆It consists of four-process nesting CNC machine, edge banding machine, saw blade side drilling machine, panel saw, curved and straight edge banding machine, single-head hinge boring machine, and profiling corner trimming machine. It can be used to process panel furniture, cabinets, closets, children’s furniture, and so on.

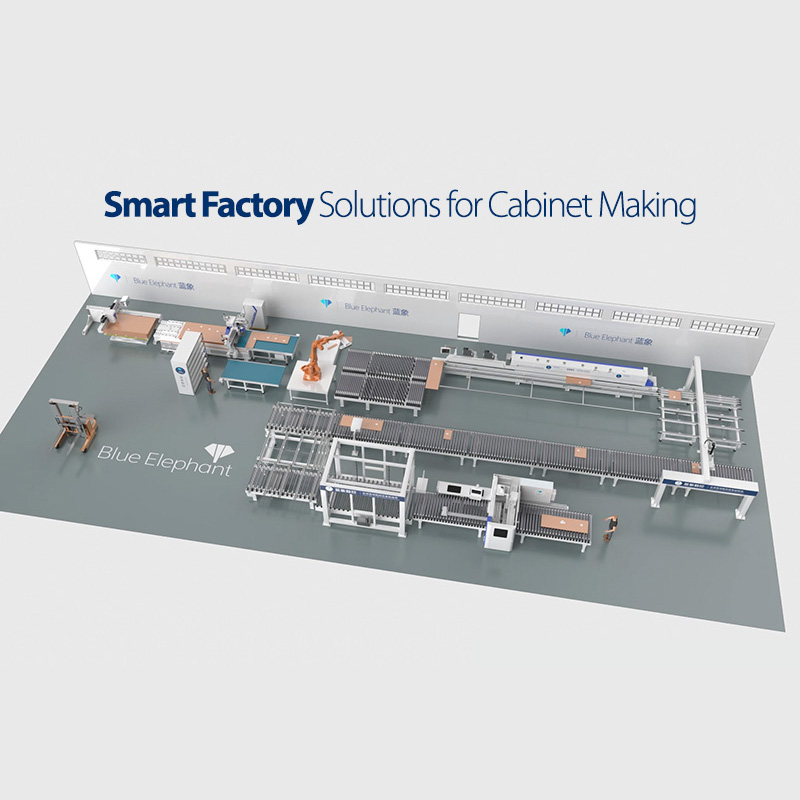

SMART FACTORY VIDEO

Features

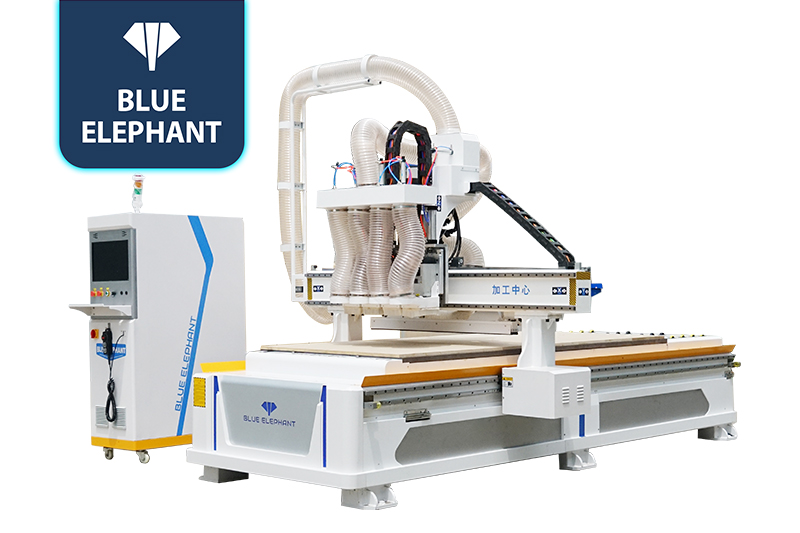

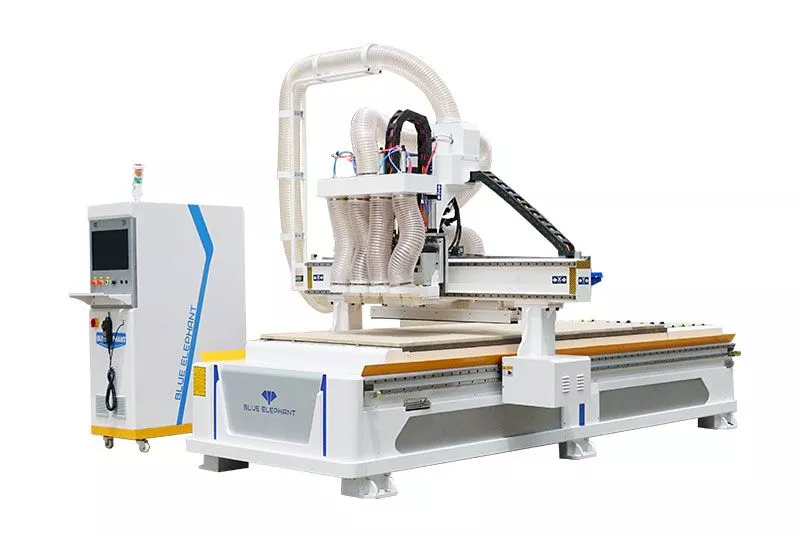

Four-process nesting CNC machine:

Introduction: The four-process nesting CNC machine is a cost-effective CNC cutting machine, combining manually assisted loading, automatic positioning, optimized automatic cutting, punching and slotting in one machine. It replaces the traditional sliding table saw and electronic cutting saw, gets rid of the dependence of traditional cutting on human workers, and can cut and drill holes at the same time.

Features:

- Equipped with 4 spindles, it can change tools automatically, save tool changing time and increase production efficiency.

- The new-style large square tubes and LED lamps on the machine body ensure both heavy load capacity and good-looking.

- The vacuum adsorption table has high adsorption force and avoids slide of panels during processing.

- It can change tools automatically, and multiple spindles can work simultaneously, greatly improving processing efficiency.

Edge banding machine:

Introduction: Full-automatic edging banding machine is mainly used for banding the edges of panel furniture, making the panel more beautiful.

Features:

- Simple operation and high precision.

- It has multiple functions, such as applying glue, aligning head and end of panels, rough trimming, fine trimming, edging, polishing etc.

- High-speed motor is adopted for high quality fine trimming.

- The fully-enclosed transparent acrylic protection hood is convenient for checking work conditions in time.

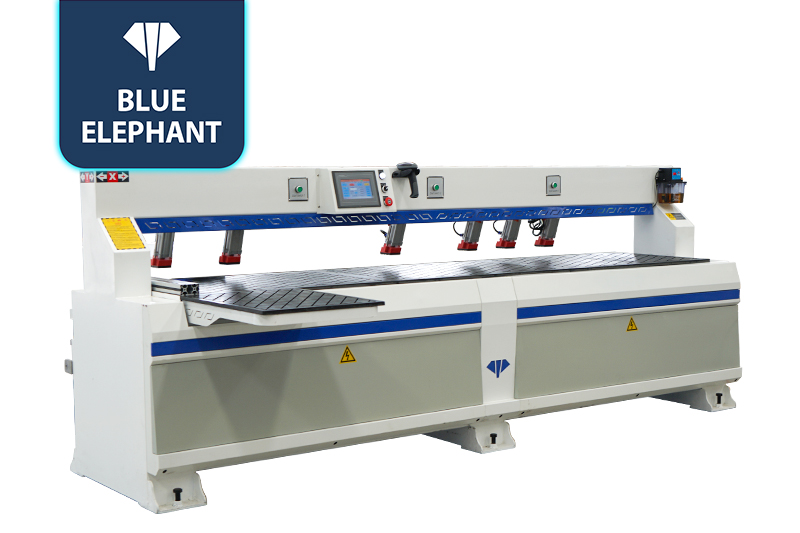

Side drilling machine:

Introduction: The side drilling machine is designed for panel furniture and cabinets, such as wardrobes, closets. It is capable for the side drilling work of three-in-one side holes/wood pinholes/blind holes/fixed groove/straight slot/four invisible parts.

Features:

- With smart drilling, it has no need to pay attention to the panel size; and it can judge the drilling position by accurate positioning with laser canning.

- Customized limit switch, protects human safety.

- It can drill holes immediately after the panel is put on the machine, without swiping bar code, which is more quick and convenient.

- Free switching among multiple drilling modes is allowed to meet various processing requirements.

Precision saw:

Introduction: Precision saw is used for the longitudinal sectioning and cross-cutting work of various board materials, such as density fiberboard, particle boards, artificial boards, ABS boards, PVC boards, PMMA, solid wood panels and other panels with similar hardness.

Features:

- European guiding rule can avoid displacement and ensure precision of panel cutting.

- Movable worktable is made of extruded aluminum alloy with high strength and no deformation.

- Extended and enhanced machine body ensures the machine stability during working.

Curved and straight edge banding machine:

Introduction: The curved and straight edge banding machine is applicable for the banding work for straight and irregular edges of the panels.

Features:

- Flexible switching between curved and straight edge banding mode is allowed without interference and misoperation, which is accurate and convenient.

- With a limit switch, the machine can be shut down automatically.

- It is capable for processing such materials as: PVC, wood veneer, melamine, plastic etc.

Single-head hinge drill machine:

Introduction: The single-head boring machine is mainly applied to the boring of furniture door hinges, such as cabinet doors, wardrobe doors, office and household furniture doors. It is able to adjust the boring position in both longitudinal and horizontal position in order to accommodate the boring requirements in a fast and convenient manner.

Features:

- The drill package design ensures small noise and durable use.

- A positioning baffle and an accurate scale are adopted, which can be adjusted based on work demands.

- Controlled by a foot switch, it is convenient and labor saving.

- Pure copper motor core is adopted to ensure smooth running and use convenience.

Profiling corner trimming machine:

Introduction: The profiling corner trimming machine is used to trim the cabinet doors after the doors’ edges are banded. The cabinet doors after trimming have smooth and consistent corners.

Features:

- It is capable for trimming the R-shape arc angle and the dimension of the angle can be adjusted with high efficiency.

- The precision cutter head adopted can achieve good trimming effect without errors.

- A protection hood is used to cover the cutter head, effectively protecting the safety of operators.

- Compact size makes it convenient to move the machine according to actual situation.

- Preferential price, time and labor saving, low cost and high efficiency.

Production Facility

Quality Control & Testing